Composite Nike Fins

I asked for additional suggestions for how-to videos and one of the requested ones was laminating fins. So, I decided to make this a little more complex by showing several techniques at once in the process of making Nike style built-up fins with a realistic profile. The Nike is a perennial favorite for modeling, plus it has an unusual fin profile, so it makes a good subject.

This illustrates several techniques in composite construction, including two different types of vacuum bagging with the FoodSaver®.

Here are the highlights from the video:

- Using the FoodSaver for vacuum bagging

- A flat lamination using a base board

- Creating a built-up profile from balsa

- Lamination of a complex fin profile

Downscaling the Prototype

I decided to plan these fins for a 4" model of the prototype (based on a standard 3.9" airframe tube).

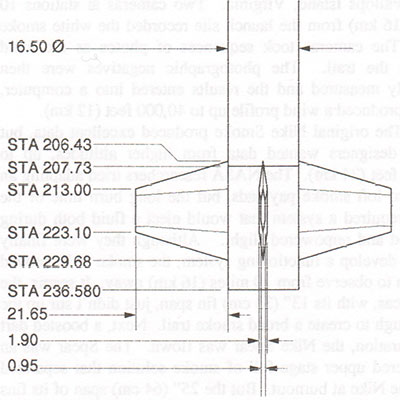

Above is a close-up of the drawing from Rockets of the World, p. 164, showing the dimensions for an actual Nike fin (from the Nike-Smoke drawings). To scale our fin to standard 3.9" I.D. tubing (4.03" O.D.), plus a through-the-wall tab to a 3" MMT:

- Use diameter to get scale: (model) 4.03" / (prototype) 16.50" = 0.244×

- Scale other dimensions by this: prototype × 0.244 = model

- Semi-span: 21.65" × 0.244 = 5.28"

- Root chord: (229.68 − 206.43) × 0.244 = 5.67"

- Tip chord: (223.10 − 213.00) × 0.244 = 2.46"

- Root thickness: 1.90 × 0.244 = 0.46"

- Tip thickness: 0.95 × 0.244 = 0.23"

- Through-the-wall tab: 0.45" (measured)

And here is my drawing at model size.